Tyre Protection Chains are manufactured from a special mesh of high wear resistant but flexible Chrome, Manganese and Molybdenum alloy steel links. The mesh protects both the side walls and the tread of the expensive tyres from wear and tear. On the other hand, Tyre Protection Chains are flexible enough to take the shape of the tyre to ensure flawless operation. In addition, this flexibility prevents potential clogging of the chains that could affect the handling of the loader.

SAVE YOUR TYRES!

Wheel loader and other earth moving machine tyres are vulnerable and expensive and they increase the operational costs. By applying this simple protection, you cannot only reduce costs, but ensure higher productivity with additional benefits.

TESTED QUALITY

We keep quality under constant control and perform regular tensile, rupture and elongation tests in metal testing laboratories. The surface hardness and core hardness are checked with Micro Vickers and HRC hardness testers. The steel for the protection chains is manufactured in the EU and is hardened by forging with 600, 800 and 1000 tonne Hydraulic Pneumatic Hammers, with 5 hits per link.

TECHNICAL SUPPORT

Our trained technicians provide on-site installation and training for future maintenance along with spare parts, special tools and accessories, which are essential for delivering best performance and ensuring long service life of the product.

THE RIGHT CHOICE FOR YOUR NEEDS

YUDIN EQUIPMENT is ready to advise on what would be the best products for your specific applications. Get in contact with us today to discuss your needs.

Application Areas: Scrapyard, Recycling, Underground Mining, Construction, Tunnel.

Pod Dimensions (W x H x B): 29x39x61mm.

Engine Power: 42 kW - 125 kW.

Operating Weight: 3 - 20 Tones.

Tyre Size: 7.50 × 15 - 10 × 16.5 - 12 × 16.5 - 17.5 × 25 - 20.5 × 25 - 23.5 × 25.

Application Areas: Underground Mining, Hot Slag, Scrapyard, Recycling.

Pod Dimensions (W x H x B): 36x44x76 mm.

Engine Power: 42kW - 125 Kw.

Operating Weight: 3 - 20 tons.

Tyre Size: 7.50 × 15 - 10 × 16.5 - 12 × 16.5 - 17.5 × 25 - 20.5 × 25 - 23.5 × 25 - 16.00 × 25.

Application Areas: Scrapyard, Recycling, Underground Mining, Hot Slag, Open Pit Metal Mining.

Pod Dimensions (W x H x B): 42x56x83 mm.

Engine Power: 115kW - 274 kW.

Operating Weight: 15 - 40 tons.

Tyre Size: 16.00 × 25 - 18.00 × 25 - 23.5 × 25 - 26.5 × 25.

Application Areas: Granite Quarry, Open Pit Metal Mining, Hot Slag, Scrapyard, Recycling.

Pod Dimensions (W x H x B): 46x66x93 mm.

Engine Power: 199 kW - 403 kW.

Operating Weight: 25 - 82 tons.

Tyre Size: 23.5 × 25 - 26.5 × 25 - 29.5 × 25 - 35 / 65-33.

Application Areas: Open Pit Metal Mining.

Pod Dimensions (W x H x B): 58x77x110 mm.

Engine Power: 520 kW - 1092 kW.

Operating Weight: 80 - 200 Tones.

Tyre Size: 45 / 65-39 - 45 / 65-45 - 50 / 65-51 - 50 / 80-57.

Application Areas: Scrapyard, Recycling, Quarry, Construction, Tunnel.

Pod Dimensions (W x H x B): 23x46x78 mm.

Engine Power: 70 kW - 125 kW.

Operating Weight: 10 - 28 tons.

Tyre Size: 17.5 × 25 - 20.5 × 25 - 23.5 × 25.

Application Areas: Granite/Marble Quarry, Open Pit Metal Mining.

Pod Dimensions (W x H x B): 30x60x99 mm.

Engine Power: 274 kW - 403 kW.

Operating Weight: 56 - 82 tons.

Tyre Size: 26.5 × 25 - 29.5 × 25 - 35 / 65-33.

Application Areas: Granite Quarry, Open Pit Metal Mining.

Pod Dimensions (W x H x B): 36x70x110 mm.

Engine Power: 403 kW - 607 kW.

Operating Weight: 50 - 100 tons.

Tyre Size: 35 / 65-33 - 40 / 65-39 - 45 / 65-45.

Application Areas: Open Pit Metal Mining.

Pod Dimensions (W x H x B): 61x85x115 mm.

Engine Power: 720 kW - 1,715 kW.

Operating Weight: 130 - 400 tons.

Tyre Size: 50 / 65-51 - 50 / 80-57 - 53 / 85-57 - 60 / 80-57.

Application Areas: Scrapyard, Recycling, Quarry, Marble/Limestone Quarry, Construction, Tunnel.

Pod Dimensions (W x H x B): 24x50x81 mm.

Engine Power: 115 - 274 kW.

Operating Weight: 15 - 35 tons.

Tyre Size: 17.5 × 25 - 20.5 × 25 - 23.5 × 25 - 26.5 × 25 - 29.5 × 25.

Application Areas: Marble Quarry, Quarry.

Pod Dimensions (W x H x B): 23x54x92 mm.

Engine Power: 274 kW - 403 kW.

Operating Weight: 56 - 82 tons.

Tyre Size: 26.5 × 25 - 29.5 × 25 - 35 / 65-33.

Application Areas: Underground Mining.

Pod Dimensions (W x H x B): 46x66x93 mm.

Engine Power: 199 kW - 403 kW.

Operating Weight: 25 - 82 tons.

Tyre Size: 18.00 × 25 - 23.5 × 25 - 26.5 × 25 - 29.5 × 25 - 35 / 65-33.

Application Areas: Underground Mining, Hot Slag, Open Pit Metal Mining.

Pod Dimensions (W x H x B): 50x71x105 mm.

Engine Power: 199 kW - 607 kW.

Operating Weight: 25 - 82 tons.

Tyre Size: 18.00 × 25 - 23.5 × 25 - 26.5 × 25 - 29.5 × 25 - 35 / 65-33.

A square mesh pattern provides the maximum protection for your tyres and is a good choice for high abrasion applications.

If you require better traction and protection of your tyres then hexagon mesh is the best option for specific surfaces.

Deca mesh provides excellent traction characteristics. This mesh pattern allows for wide self-cleaning areas and can be used for lower abrasion applications.

- Save wear on the expensive tyres

- Maximise equipment availability due to shoerter down times

- Better traction characteristics

- Significantly extended tyre service life

- Maximum tyre protection

- Suitable for high and low abrasion applications

- Fits A wide range of machines

- Diversity in application areas

- Can withstand temperatures up to 1000 °C

- Environmentally friendly manufacturing

- Highest quality raw steel materials

- Warranty and quality certificates

- Improved productivity of the loaders

- Shorter down times

- Fewer unplanned stops for servicing

- Lower fuel consumption

- Reduced operational costs

- Optimal final product price

- Quarrying

- Mining

- Slag Processing

- Scrap Handling

- Underground Works

- Tunnelling Works

- Construction

- Marble Quarries

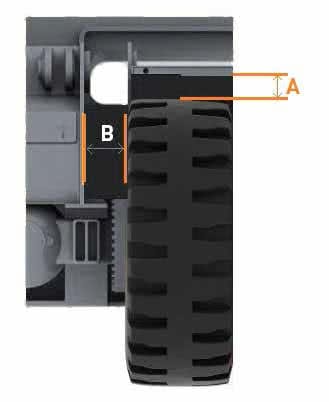

Recommended clearance for Tyre Protection Chains

|

MODELS |

A |

B | |

|

X12 UNIVERSAL |

42 mm (1.65”) |

62 mm (2.4”) |

|

|

X14 ROYALROCK |

50 mm (2”) |

74 mm (2.9”) |

|

|

X16 SUPERSTONE |

56 mm (2.2”) |

82 mm (3.2”) |

|

|

X18 ULTRA |

56 mm (2.2”) |

82 mm (3.2”) |

|

|

X18 ROYARLOCK |

68 mm (2.6”) |

98 mm (3.8”) |

|

|

X18 UNIVERSAL |

72 mm (2.8”) |

100 mm (4”) |

|

|

X20 ROYALROCK |

82 mm (3.2”) |

104 mm (4.1”) |

|

|

X22 UNIVERSAL |

90 mm (3.5”) |

110 mm (4.3”) |

|

|

X23 ROYALROCK |

100 mm (4”) |

120 mm (4.7”) |

,210_big.jpg)

Quarrying Tyre Protection Chains

Quarrying Tyre Protection Chains

Mining Tyre Protection Chains

Mining Tyre Protection Chains

Slag and Scrap Handling Chains

Slag and Scrap Handling Chains

Underground/Tunneling Chains

Underground/Tunneling Chains